Develop future together

To the jobsHuman Resources

Nicole Heyde, Carolin Heinze

Katharina Zenner & Marlene Körner

Climbing up with team & spirit

The structural developments of Industry 4.0 and IoT, as well as increasing demands on security and cyber resilience, present new challenges for mechanical engineering. With our comprehensive solutions, ranging from control systems and connectivity to service portals, we offer added value for mechanical engineering, which we round off with answers to these topics. Together with you, we stand by mechanical engineering as a team with our experience.

YOUR TASKS

• Advise customers in the field of mechanical and plant engineering on the topics of control software, plant visualization, connectivity, security, and cyber resilience.

• Identify the goals and potential areas of relief for customers with regard to our solutions.

• During initial contact, you will present our software solutions in a convincing manner and advise our customers individually.

• Together with our Inside Sales team, you will prepare quotations that reflect customer requirements and the results of customer workshops.

• You enjoy acquiring new customers. You will work with our marketing team on the strategy for implementing this.

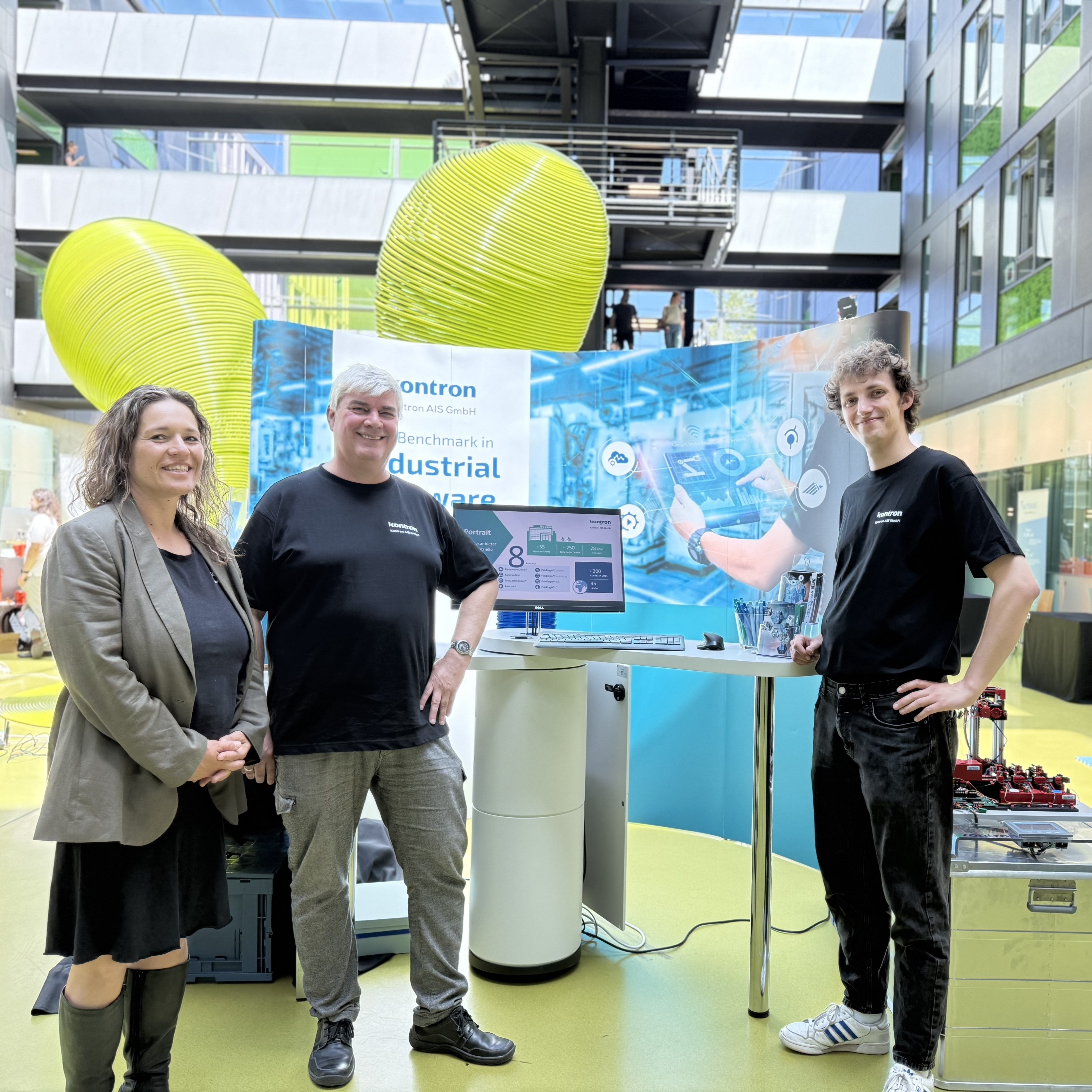

• At trade fairs, you will establish initial contacts and impress as a competent contact person for our solutions.

• As part of a team, you will focus on topics such as presentations, pitches, webinars, or content for the next trade fair.

Your profil - what you bring to the table ...

- … Sales experience and/or experience in project management.

- You have a technical background in mechanical and plant engineering and have already gained experience in the field of manufacturing automation.

- Ideally, you complement your expertise with industry and competitive knowledge in the fields of mechanical engineering, manufacturing, and production.

- You are characterized by a strong customer focus, entrepreneurial thinking, a willingness to travel internationally, and business fluent English skills.

- Communication and a confident, convincing, and authentic manner are your strengths.

- You impress with your high level of self-motivation, commitment, flexibility, and team spirit.

your benefits

- With us, you will find a working environment where you feel at home.

- Flexible working hours and working from home give you real freedom to achieve a good work-life balance.

- Look forward to structured onboarding with regular feedback meetings that actively support you and strengthen you in the long term.

- Your personal and professional development is particularly important to us.

- You will benefit from cross-departmental networking at team and company events – for more exchange of ideas, transparency, and innovation.

- You can take advantage of our numerous benefits, such as health services, continuing education opportunities, and various subsidies.

Apply now!

The megatrends of digitalization and the IoT are presenting new challenges, especially for machinery and plant engineering, and more generally for all manufacturers of connected devices, in dealing with software, hardware, and cybersecurity. Together with you, we stand as a team, combining our experience to deliver solutions with Kontron AIS software and hardware products from the Kontron Group.

YOUR CHALLENGE

- Advise industrial customers in the fields of machinery, plant engineering, and equipment manufacturing on IoT and embedded solutions.

- Identify requirements and determine ways to implement them in cooperation with — and using the products of — the Kontron Group.

- In initial customer interactions, it is your task to convince them through presentations and consulting.

- Working closely with the development team, you develop solution proposals.

- Together with the internal sales team, you prepare offers that reflect customer requirements and the results of customer workshops.

- You enjoy acquiring new customers and working with sales partners, and you collaborate with our marketing team on strategies to implement the Group-wide IoT strategy.

- At trade shows, you establish first contacts and convince prospects as a point of contact for our solutions.

- Within the team, you focus on topics such as presentations, pitches, webinars, or preparing content for the next trade show.

YOUR BENEFITS

- Permanent full-time employment

- Hybrid working model, home office options, and flexible working hours

- Genuine teamwork at eye level: you matter to us!

- Personal and professional development opportunities

- Regular team and company events

- JobTicket and JobRad (bike leasing) to support sustainable commuting

- Weekly massage appointments, fresh fruit, and unlimited coffee

Various subsidies: TicketPlus card, company pension plan, and gym membership

YOUR PROFILE

- You have sales experience and/or experience in project management.

- You have a technical background in industrial software and embedded solutions.

- You stand out through strong customer orientation, entrepreneurial thinking, and a willingness to travel internationally (with business-fluent English skills).

- Communication skills, as well as a trustworthy and confident manner, are among your strengths.

- You demonstrate a high level of self-motivation, commitment, flexibility, and team spirit.

- You have industry and market knowledge in mechanical and plant engineering or in the field of embedded solutions.

Apply now!

The megatrends of Industry 4.0 and the IoT are driving digitalization in the machinery and plant engineering sectors, presenting companies with new challenges in dealing with modern control systems, connected data, cloud-based software platforms, and standardized interfaces, as well as rethinking processes and managing the cultural transformation of business practices.

Together with you, we aim to set new standards in industrial manufacturing with our software solutions while always ensuring the highest level of safety, especially in the pharmaceutical sector. Together with you, we put our guiding principle into practice: “The Benchmark in Industrial Software.”

YOUR CHALLENGE

- Performing qualification/validation of our computer systems (e.g. FabEagle® Leitrechner) as well as computer-based systems in the pharmaceutical environment at our customers’ sites (Germany, Europe, worldwide).

- Creating GMP concepts and qualification documents, such as Functional Requirement Specifications, risk analyses, IQ and OQ test plans.

- Supporting our project managers in planning the qualification/validation within the respective projects.

- Optimizing workflows related to validations and supporting qualification activities for computer systems.

- Supporting the team with change management and ensuring compliance with GMP-relevant processes.

- Continuously improving processes and requirements by contributing suggestions and adapting the relevant documents.

- Supporting the team or specialist departments during external and internal audits in the GMP environment.

- You will be a permanent member of our team — your opinions, ideas, and suggestions are very important to us.

YOUR BENEFITS

- Flat hierarchies, short communication channels & an open environment are important to us for a smooth cooperation

- For the development of each team member, we offer an extensive range of further training (professional & personal)

- A real work-life-balance culture is very important to us in enabling all employees to achieve the ideal balance between family and career

- Sport/team events strengthen team spirit and cohesion

- At weekly massage treatments you can switch off for a short while and recharge your batteries

- You can expect an unlimited permanent position & 30 days holiday

YOUR PROFILE

- You have a completed academic degree in a scientific or engineering field (e.g., computer science, automation technology, pharmaceutical engineering, or a comparable discipline) with initial professional experience.

- You are familiar with national and international pharmaceutical regulations in the GMP environment (e.g., GAMP 5, EU GMP Guidelines, 21 CFR Part 11/210, etc.).

- You take responsibility for your projects and stand out through careful documentation of your work.

- Communication skills, as well as a confident and trustworthy manner with customers, are among your strengths.

- You demonstrate a high level of self-motivation, commitment, independence, flexibility, and team spirit.

- You are highly willing to travel, meaning multi-week business trips (potentially several times per year) are something you enjoy.

- Good spoken and written English skills complete your profile.

Apply now!

Do you want to be part of a new generation of our established control software ToolCommander® ToolCommander® - Software for machine control and visualization (kontron-ais.com) and FabLink® FabLink® suite - SECS/GEM interface solution for your machines (kontron-ais.com), conquering Industry 4.0 and IoT worldwide? Then join us and become part of our success story! Together with you, we want to leverage the high potential in automation with innovative ideas and implement our vision of making the impossible possible. In our team, we value fun, creativity, connection, trust, freedom, knowledge transfer, and genuine sustainability.

As an Application Engineer in the field of product development and support, you will take on a central role that contributes greatly to the success of our company.

YOUR CHALLENGE

• You are the link between product development and project implementation in the field of machine controls and provide significant support in implementing control solutions.

• You validate existing equipment directly with customers and incorporate new requirements into subsequent development for product extensions using .NET 6 and C#.

• As the first point of contact, you support and advise our existing customers and work with the team to develop solutions for technological challenges in a smooth operation in the factory.

• You act as a product consultant in machine control, share your knowledge in practical workshops, and authentically and convincingly present application possibilities.

YOUR PREFERD PROFILE

- You are an enthusiastic software developer with a lot of commitment, high self-motivation, goal orientation, and flexibility, for whom a combination of software development and customer care and advice is exactly the right thing.

- Good communication, also in English (B1), as well as a trustworthy and convincing appearance characterize you.

- You have in-depth knowledge of C# and handling .NET and have expertise in computer science, automation technology, or similar degrees in engineering or natural sciences.

- Ideally, you have practical experience in automation, machine control, and integration

WHAT TO EXPECT

- An interesting and challenging task, modern technology and development tools, and a highly motivated team with a common vision

- Room for creativity: professional and personal development opportunities through individual training programs

- A flat organizational structure through self-organized teams, short communication paths, and open doors

- A work-life balance culture with individual working hours, trust-based working hours and flexible working models

- You will be a permanent team member and we value your opinion, ideas and suggestions

- A motivating and appreciative working atmosphere with massage appointments, sports and team events, as well as various company events

- A permanent employment contract, 30 days of vacation, and annual feedback meetings

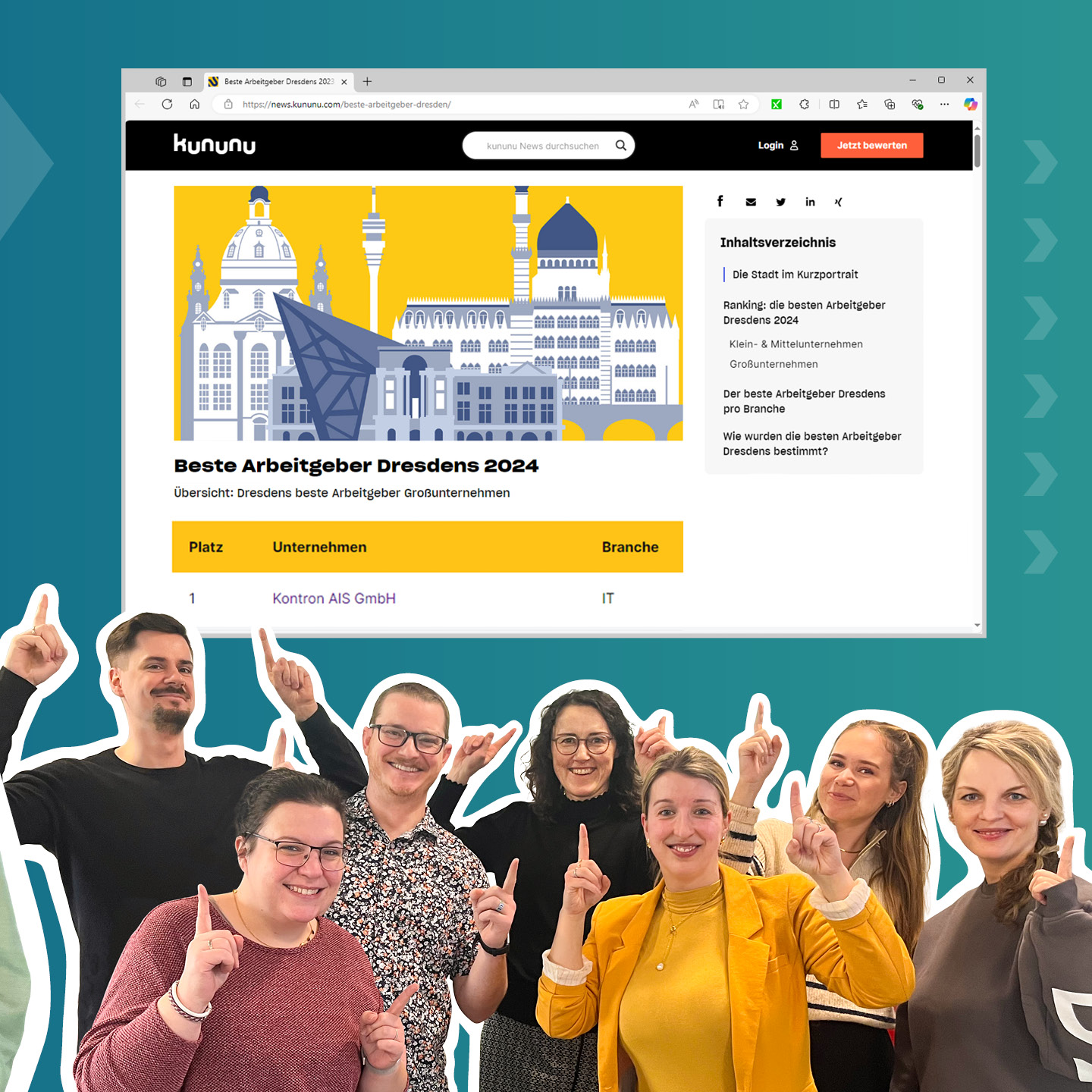

- Check out Kununu to get a realistic picture of our company at Kontron AIS als Arbeitgeber: Gehalt, Karriere, Benefits (kununu.com).

Apply now!

The digital transformation through Industry 4.0 and IoT is changing the industrial world and we are right in the middle of it. In projects for sectors such as semiconductors, automotive, pharmaceuticals and photovoltaics, we develop smart software solutions for modern manufacturing processes. We rely on modern technologies, team spirit and creative solutions. Are you an enthusiastic Senior Software Developer who works responsibly, goal-orientated and independently? Then you've come to the right place.

YOUR AREAS OF WORK WITH US

Backend development (C#, .NET)You will work on innovative solutions in various industrial areas - e.g:

- Manufacturing Execution Systems (MES)

- Tool automation and factory automation

- Application Engineering and Host Interface

- Equipment control and field service

Web and cloud applications

- Development of modern web applications with technologies such as Oracle APEX, CSS, Java

Quality assurance

- Implementation of test automation as part of our quality assurance engineering

Our software technologies:

- C#

- ORACLE APEX

- SQL

- Angular

- JavaScript,

- TypeScript

- NodeRed

- Siemens S7

WHAT YOU BRING WITH YOU

- Enjoyment and passion for developing software

- Skills in one or more areas of our SW technologies

- Creativity to optimise customer-specific solutions

- Ideally initial experience in an industrial environment

- Team spirit and ability to work independently

- A good level of communication

- Good English Knowledge

WHAT YOU CAN EXPECT

- With us you will find a working environment that makes you feel good

- Flexible working hours and working from home give you real freedom for your personal and professional balance

- You can look forward to a structured induction programme with regular feedback meetings that actively support and strengthen you in the long term

- Your personal and professional development is particularly important to us

- You benefit from cross-divisional networking at team and company events - for more exchange of ideas, transparency and innovation

- You can take advantage of our numerous benefits, such as Health offers and further training opportunities through to various allowances

Apply now!

The digitalization driven by the megatrends of Industry 4.0 and the IoT is presenting companies in the machinery and plant engineering sectors with new challenges in dealing with modern control systems, connected data, cloud-based software platforms, standardized interfaces, and regulatory requirements. Together with you, we stand as a team, using our experience to enable smart manufacturing for a digital future, while also offering our customers software services.

YOUR CHALLENGE

- In inside sales, you support the continuous servicing of existing customers in close cooperation with our sales managers.

- You handle the content and pricing of quotations, as well as processing order confirmations and purchase orders.

- You continuously document sales activities in the CRM system.

- You will gradually take over the management of existing customer accounts.

- To help expand our customer base, you support market research, market monitoring, and customer acquisition efforts.

- You work closely with the marketing, product, and project teams to optimize our customer communication.

YOUR PROFILE

- You already have initial experience in inside sales.

- You have successfully completed a commercial or technical education, with initial or several years of professional experience in inside sales, customer support, or new customer acquisition — ideally in a technical environment.

- You stand out through strong customer orientation and entrepreneurial thinking.

- You are communicative and present yourself in a trustworthy and convincing manner.

- You demonstrate a high level of self-motivation, commitment, flexibility, and team spirit.

- You are communicative and enjoy interacting with people.

- You are goal-oriented and work independently.

- You have good spoken and written English skills.

YOUR BENEFITS

- Permanent full-time employment

- Hybrid working model, home office options, and flexible working hours

- Genuine teamwork at eye level: you matter to us!

- Personal and professional development opportunities

- Regular team and company events

- JobTicket and JobRad (bike leasing) for sustainable commuting

- Weekly massage appointments, fresh fruit, and unlimited coffee

- Various subsidies: TicketPlus card, company pension plan, and gym membership

INTERESTED?

Apply now, we look forward to getting to know you! If you have any questions beforehand, feel free to contact us at +49 351 21661075. Nicole Heyde & Carolin Heinze will be happy to answer any questions you may have about the position.

Apply now!

Apply now!

The digitalization driven by the megatrends of Industry 4.0 and the IoT is presenting companies in the machinery and plant engineering sectors with new challenges in dealing with modern control systems, connected data, cloud-based software platforms, and standardized interfaces. Together with you, we stand as a team, using our experience to enable smart manufacturing for a digital future.

Gain experience in an internship or as a working student on the following topics:

Creating unit tests for project-specific extensions

FabEagle®Monitoring is our factory-wide shop floor management solution for the entire production environment. With this monitoring system and its machine and production data acquisition (MDE/BDE), our customers benefit from a clear visualization of their machines and equipment. The focus is on monitoring and displaying machine states, quantities, alarms, and maintenance — all in individually configurable dashboards and reports.

Test cases for extensions

- The function “Create Fire Protection Responder/First Aider” (EMH) — an ideal project for getting to know utPLSQL

- REST API “AndonBoard” (EMH)

- REST API “BI Tool” (EMH)

- Developing ideas for automation in the build process

YOUR PROFILE

- Initial knowledge of the utPLSQL tool

- Required prior knowledge of SQL and general programming skills

- PL/SQL knowledge is a plus

YOUR BENEFITS

- A flat organizational structure, short communication paths, and an open environment

- A challenging and exciting task that you can solve together with your professional mentor

- Flexible working hours and the option to work from home

- A comprehensive range of professional and personal development opportunities

- A genuine work-life balance culture

- Annual sports and team events

- Weekly massage appointments at the company

Apply now!

The digitalization driven by the megatrends of Industry 4.0 and the IoT is presenting companies in the machinery and plant engineering sectors with new challenges in dealing with modern control systems, connected data, cloud-based software platforms, and standardized interfaces. Together with you, we stand as a team, using our experience to enable smart manufacturing for a digital future.

Gain experience in an internship on the topic of:

Extending the Host Simulator

Kontron AIS GmbH has an object-oriented, graphical development tool that enables our employees to efficiently develop modern control systems.

To test these control systems, an in-house testing tool was developed that enables comprehensive SECS/GEM testing (SEMI Equipment Communications Standard / Generic Equipment Model).

The goal of this internship is to further develop this testing tool. This includes resolving existing issues, implementing new functions, and verifying the correctness of all changes through developer testing.

YOUR CHALLENGE

- Getting familiar with the development tool VAC NT/32

- Using Azure DevOps

- Working with a backlog/Kanban board

- Creating design specifications followed by a design review with experienced colleagues

- Implementing the developed designs in C#, .NET 4.8, and VAC NT/32

- Performing developer tests for quality assurance

- Documenting the changes made

YOUR PROFILE

- Basic knowledge of C#

- Experience with .NET is an advantage

- Experience with graphical programming is desirable

- Interest in automation and technical software development

- An independent and structured way of working

YOUR BENEFITS

- A flat organizational structure, short communication channels, and an open environment

- A challenging and exciting task that you will solve together with your professional mentor

- Flexible working hours and the option to work from home

- A comprehensive range of professional and personal development opportunities

- A genuine work-life balance culture

- Annual sports and team events

- Weekly massage appointments at the company

Apply now!

Die mit den Megatrends Industrie 4.0 und IoT in den Maschinen- und Anlagenbau einziehende Digitalisierung stellt Unternehmen vor neue Herausforderungen im Umgang mit modernen Anlagensteuerungen, vernetzten Daten, Cloud-basierten Softwareplattformen und standardisierten Schnittstellen. Gemeinsam mit Dir stehen wir als Team mit unserer Erfahrung für eine smarte Fertigung in einer digitalen Zukunft.

Schreibe Deine Abschlussarbeit zu folgenden Themen:

Architekturbetrachtung zu „Datennahen“ Applikation – Sind Datenbank Agnostische Applikation realisierbar und sinnvoll? (Manufacturing Automation)

- Realisierbarkeit der Datenbank Agnostik

- Vor- und Nachtteile von Code in den Daten

- Untersuchung verschiedener Datenbanksysteme im Hinblick Code in der Datenbank

- Architekturentscheidung für Projekte im KAIS Umfeld

WAS DICH BEI UNS ERWARTET

- flache Organisationsstruktur, kurze Kommunikationswege & ein offenes Umfeld

- eine fordernde sowie spannende Aufgabe, die du gemeinsam mit deinem Fachpaten lösen kannst

- flexible Arbeitszeiteinteilung sowie die Möglichkeit zum Arbeiten im Homeoffice

- ein umfangreiches Weiterbildungsangebot (fachlich & persönlich)

- eine gelebte Work-Life-Balance-Kultur

- jährliche Sport- & Teamevents

- wöchentliche Massagetermine im Unternehmen

Apply now!

Erstelle ein Design- und Integrationskonzept für ein Equipment Performance Monitoring Modul als Komponente eines Equipment Engineering Systems (EES Framework) für den Einsatz in hochautomatisierten Fabriken der Halbleiter-, Photovoltaikindustrie und LED-Fertigung.

In den letzten Jahren ist ein nachhaltiger Anstieg in der Anwendung von Advanced Process Control (APC) Methoden in der Halbleiterbranche, LED und Photovoltaik zu verzeichnen. Dieser Aufschwung kann auf den starken Wettbewerb, die Notwendigkeit zur Kostenreduktion, die Entwicklung immer kleinerer Chip-Technologien und effizienterer Zellen und daraus folgend der Druck auf Prozessstabilität und Gewinn – zurückgeführt werden. Equipment Performance Monitoring verbunden mit Fault Detection and Classification (FDC) sind APC Disziplinen, die sich nicht nur auf die Erkennung von Maschinenfehlern beschränkt, sondern das Ziel verfolgt die Quelle des Fehlers zu identifizieren, um somit die Produktivität der Maschinen zu steigern.

Mit dieser Arbeit soll ein Konzept für die Integration des EPT Moduls TFM (Total Fab Monitoring) der Kontron AIS in das EES Data Framework der Kontron AIS entwickelt werden.

Bei der Bearbeitung erhält man einen Einblick in aktuelle Chipfertigung und Zellproduktion deren Prozessabläufe und Automatisierung und kann sich mit den neuesten Technologien, Standards und Trends vertraut machen.

DEINE AUFGABEN

- Analyse des bestehenden EPT Module (TFM) und des EES Data Client Framework (EES) seiner Module und Schnittstellen

- Anforderungsanalyse basierend auf einem Studium und Bewertung der von SEMI definierten standardisierten Funktionen für EPT (SEMI E10).

- Ausarbeitung eines Designkonzepts für die Implementierung

- Prototypischer Entwurf, Implementation und Test

- Aufbau eines Demonstrators und Dokumentation Lösung

- Regelmäßige Reviews und Präsentation der aktuellen Projektzwischenstände

DAS BRINGST DU MIT

- Gute Kenntnisse in .net / C#, WPF / WinForms, XML

WAS DICH BEI UNS ERWARTET

- flache Hierarchien, kurze Kommunikationswege & ein offenes Umfeld

- eine fordernde sowie spannende Aufgabe, die du gemeinsam mit deinem Fachpaten lösen kannst

- flexible Arbeitszeiteinteilung sowie die Möglichkeit zum Arbeiten im Homeoffice

- ein umfangreiches Weiterbildungsangebot (fachlich & persönlich)

- eine gelebte Work-Life-Balance-Kultur

- jährliche Sport- & Teamevents

- wöchentliche Massagetermine im Unternehmen

Apply now!

Apply now!

YOUR CHALLENGE

In the 1st year of studies, you will get to know new colleagues and your workplace, as well as your first exciting areas of responsibility. After a short training period you will be able to take over and master your first tasks independently. Your subject mentor will of course support you throughout your studies and provide you with the necessary development tools.

In the 2nd year of studies, you can apply the skills you have learned in theory more and more in your daily work at AIS and get a first taste of project work.

In the 3rd year of studies, your bachelor's thesis is on the agenda. You can count on us for this. In the daily business as a prospective software developer, you are already well equipped and work independently on projects to a great extent.

Your lectures will take place at the Berufsakademie Dresden and you will be switching between university and practice, we will of course provide the perfect connection.

The total duration of study is 6 semesters, i.e. 3 years. https://www.ba-dresden.de/

YOUR BENEFITS

- Intensive support provided by your professional sponsor

- Exchange with technical experts

- Possibility to work on development processes

- Assumption of your tuition fees

- Agile work environment

- Work-Life-Balance-Culture

- Great working atmosphere, friendly & motivated colleagues

- Various sport/team events and health sport days

- Attractive remuneration and 30 days of vacation

YOUR PROFILE

- General higher education entrance qualification or subject-related entrance qualification

- Mathematics with good performance

- Interest in computer science and technology

- Commitment, initiative and team spirit

- Enthusiasm for automation processes